DESPITE IT ALL

What a summer we had, and I don’t just mean here on the Humble Roots job site. Sweltering heat, relatively few smoke days, Fairbanks was the place to be this summer! While everyone was out enjoying the sun, I was on the end of a shovel or in the hot cab of heavy equipment most of the summer working long days trying to make some big strides.

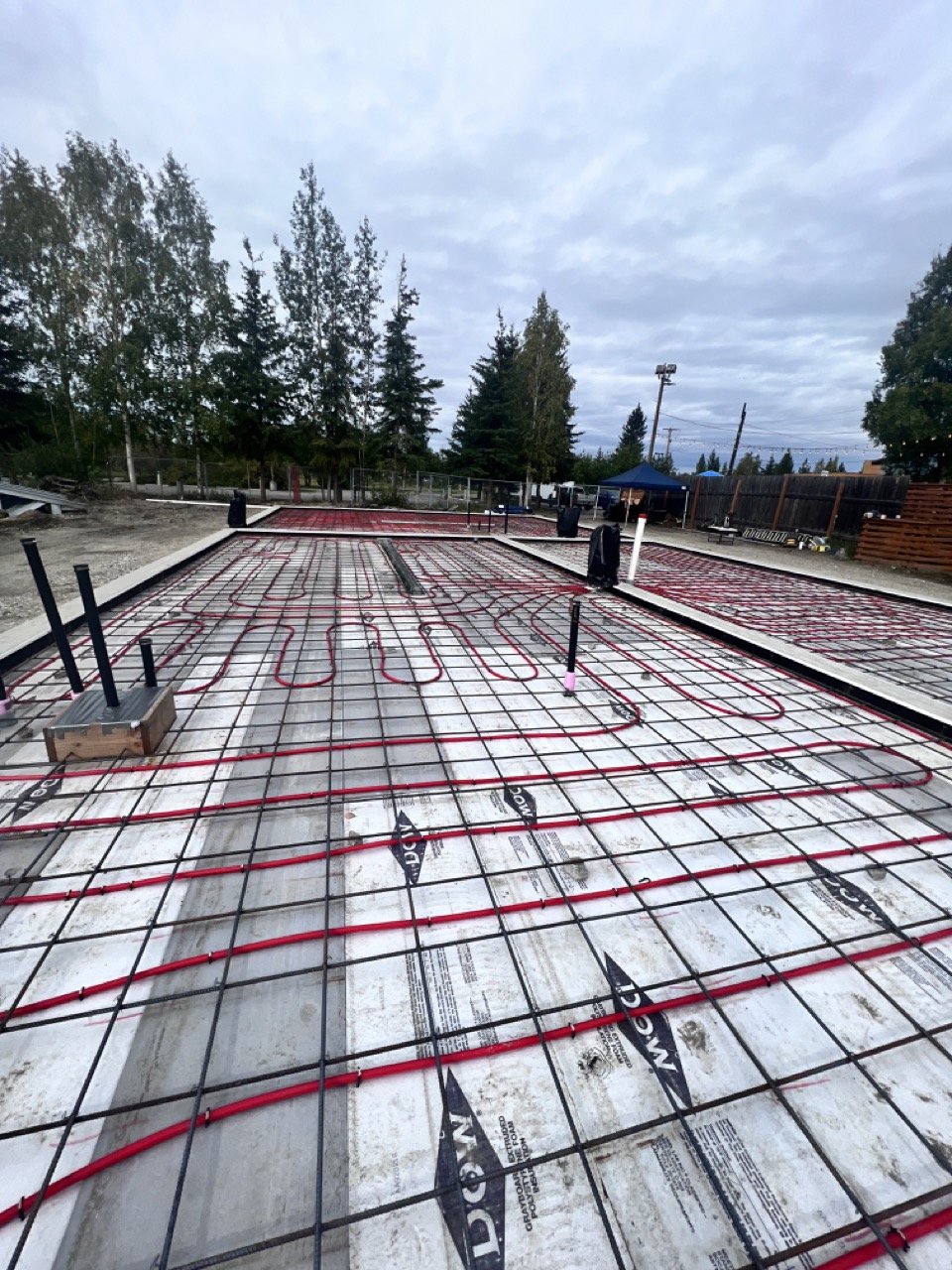

After a long push to get everything plumbed in, we put down insulation foam, radiant heating, and rebar to pour the slab!

Industry folks will tell you things like, “Fluff your expected budget by a healthy margin,” or “You just don’t know what you don’t know,” when you talk to them about building a new commercial building but they neglect to mention how long dirt work and foundation work takes! I’m reminded of a quote from O Brother, Where Art Thou? – “Aint this place a geographical oddity, two weeks from everywhere!” Well if that isn’t the perfect description of Fairbanks then I don’t know what is. That quote also describes proposed project timelines pretty perfectly when talking to contractors. Everybody is about two weeks out, and it will take about two weeks to get done.

With slabs poured, we went through and marked all the various building lines. Things finally started to take shape when we were able to walk through the future building even if it was just marked on the ground.

A whole bunch of two week projects turn into a whole bunch of months real quick and the downside to living in the subarctic is that you just simply don’t have very many months to get a lot done. That simple fact led to some long work days this summer. Despite it all, we managed to get all the dirt work accomplished to pour slabs and begin construction on our roof!

Starting with the roof…sounds odd for sure. If you drive by the property today you will see a whole bunch of shiny trusses (38 to be exact) being tied together on the slab. Why not start with walls and add the trusses on top one by one?

We are on borrowed time before snow flies this year. We have a lofty goal of getting the entire structure up and dried in before it gets too cold to work outside. By being able to work on the roof assembly on the ground, we save ourselves from having to assemble the roof 20+ feet in the air once it's already on top of walls. The only thing worse than working on a roof that’s already 20+ feet in the air, is trying to do it in the snow. This method affords us the ability to use a crane to pick up and set aside large portions of the roof, build walls, then pick the roof back up and set on top. Feel free to comment on how short our brewery looks though as you drive by and see the trusses on the foundation. I promise it will get taller!

There I am, lifting trusses one at a time into place to begin building the roof!

Our building is made up of pre-cut steel. We dramatically cut down (pun intended) on the amount of time it takes to assemble the building by not having to make any cuts in the field while building this thing. For example, all the trusses were set in place and tied together with hat channel in 3 days by 3 guys. The trickiest most time consuming part of the build is the roof system. Once that is ready to go we should be flying on building walls. Should be.

Hat channel being added to the trusses to tie them together.

Every step of this project has come with hiccups. From getting utilities to the property to long lead times on mechanical components, everything that could go wrong has definitely seemed to go wrong. Despite it all, we have pushed really hard to meet timelines with realistic expectations and are very proud of everything we accomplished this summer. When you drive by our property at 314 Wendell Avenue I hope you can see the tangible progress we’ve made with a very small team. I’ve worn many hats this summer and learned a whole lot about this type of project and look forward to the day when we have a front door for you to walk through.

Here’s to hoping we are pouring beer before next summer!